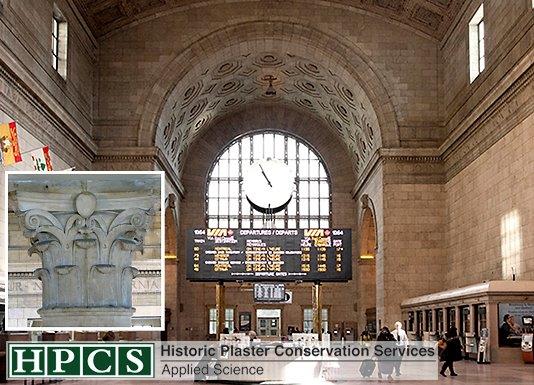

Toronto, Ontario (1927)

The Building:

Canada’s largest and busiest train station.

Project Synopsis:

Union Station is undergoing a $250 million renovation scheduled to be completed in 2020. Historic Plaster Conservation Services is the project’s plaster conservator, working with a large team, including Dima Cook the lead heritage architect for FGM Architects (FGMDA).

One of the principle issues pertains to the stone in the station’s main hall. The hall was built with a combination of quarried Zumbro stone slabs and blocks used for flat and simple work, and a composite of crushed Zumbro (artificial Zumbro) cast into ornamental shapes simulating carving.

The composite was used to make cast ornamental stone elements, a much less expensive proposition than having the details carved in quarried stone. As it turned out, real Zumbro stone ages differently than the artificial Zumbro so that the two have become distinctly different from a visual perspective since the building went up in 1927. The quarry is closed and no more stone from it is available. Alternative products that may be similar have been investigated. The conservation discussion has involved a process of confirmation that indeed the two materials were intended to be very similar or identical in appearance at the time of construction and questions about how best to ameliorate the difference in appearance have developed due to the different soiling characteristics of each. A third discussion involves what the newly minted synthetic Zumbro will look like relative to the two materials it is related to – in 50 years.

A related issue is the challenge of replacing missing pieces of Zumbro with material that matches the original. HPCS will be producing new synthetic stone in panels and blocks to match the existing. From this material, repairs to both real and artificial Zumbro will be executed “Dutchman” style where needed.

HPCS is also working with the project engineers to address any issues associated with the fibrous plaster panels that comprise the arches at each end of the main hall. These panels are suspended from the steel roof structure by a classic jute wad system. A detailed inspection is pending to determine the strength and security of the suspension.

HPCS is also responsible for overseeing the replication of an ornamental frieze, the recreation of elaborate cornice molding and the general supervision of the plaster trades doing the work.