Ottawa, Ontario (1847)

The Building: a gothic inspired edifice and a National Historic Site of Canada. The cathedral is in the centre of Ottawa, which lies above a seismic activity fault line. Our assessment of attached plaster ornament in historic buildings in Ottawa is an especially important focus of our work there.

The Wisdom of Seeking a Second Opinion

The project managers of the building had been advised by other consultants that the deteriorated plaster on the nave and aisle ceilings was beyond repair and that all of the plaster and probably the wood lath substrate would need to be removed and replaced with new plaster or drywall. As evidence, they cited water stains on the lath and suggested that the safety of occupants was being put at risk every day there was a delay in demolishing the interior finishes. This re-plastering – or worse, drywalling plan – would have required a huge demolition exercise that would have caused all the soot and dirt that had accumulated in the attic to enter the sanctuary. In the conversion of Notre Dame’s heating system from coal to natural gas many years before, the old chimneys were taken down below the roof line and abandoned there. The result over half a century was that a fine carpet of coal soot was distributed across the entire attic. All of it would have found its way into the cathedral proper under a re-plastering or drywalling exercise. The well-being of the double Casavant organ for which the cathedral is famous would have been threatened by either scheme.

The prospect of saving the plaster and its integrity without very invasive construction activity in the nave was naturally appealing to the building managers. Fortunately, Sue Monk, the architect in charge (from E.J. Cuhaci Architects), prevailed and HPCS conducted our study.

The condition assessment of the plaster was provided in a report to the project managers. The assessment process was quite an innovation in 1999. We have since formalized this process and used it many times in similar situations. For more detailed information, refer to the presentation “The Consolidation of Plain Face Plaster at Notre Dame Cathedral” outlining the plaster condition assessment process pioneered by HPCS.

The HPCS condition assessment was accepted by the project managers. It showed that across about one third of the ceiling area, up to fifty percent of the “as built” strength of the plaster had been lost and that the deterioration process, being a simple function of gravity, was ongoing and unstoppable.

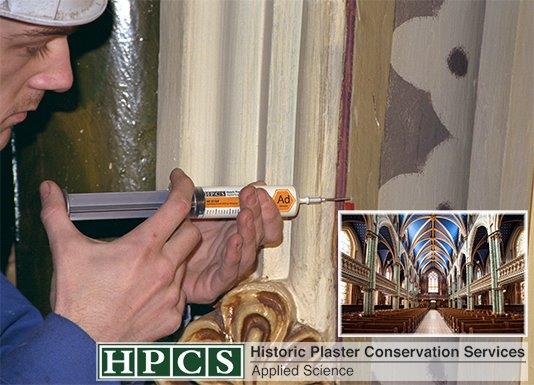

The remediation proposed by HPCS was consolidation of the ceiling plaster by flooding with acrylic resins in a controlled manner that would essentially convert the wood lath and plaster ceiling from being a weakened suspended system that depended on the lugs and keys between the wood laths for support to being a strong adhered system with a newly established bond between the plaster and the huge available surface of the wood lath.

Rest areas were completed and evaluated by third party inspectors. Costs were compared to the replacement option. The program was adopted and HPCS proceeded to consolidate the entire ceiling surface of the cathedral in a project that carried on over several months. 100% of the plaster was stabilized and retained with no losses whatsoever. An inspection in 2013 indicated no change of condition since completion.

In subsequent stages, HPCS was authorized to perform a wide range of plaster conservation activities to all of the ornament and extruded moldings in the cathedral. An interesting innovation for replacement of ornament high above the nave was the use of light and durable urethane foam as an alternate to plaster of Paris. The patterns were made and replica parts were cast in plaster of Paris, gilded and made ready for installation. The same molds were then used to make the identical parts in urethane foam with equal or greater strength at 1/24th the weight. These parts were also gilded and made ready. Based on public safety considerations, the urethane parts weighing half a pound were selected to replace the 12-pound plaster parts that had fallen off the building’s interior over the years.

Massive Crockets Pose An Interesting Challenge

The massive crockets over the sanctuary arch were an interesting challenge. Made of very thin slip cast plaster, the crockets had been held in place by piano wires and other makeshift fastenings for quite a while. We removed them all and made repairs as required – i.e. where they were cracked and in very precarious condition.

Then, skilled technicians prepared an armature system solidly connected to the structure above the sanctuary arch. The individual crockets were slid up over the armature and temporarily suspended in place. Once properly aligned, each crocket was filled with a measured amount of urethane foam, which expanded gently around the armature, filling the cavity and locking the crocket to the arch above.

Other completed work included replication of hundreds of plaster stars that were gilded and applied to the ceiling, plus structural stabilization of faux finished wood lath and plaster columns throughout the cathedral.

The entire project was successfully completed on time and within the allotted budget for each phase of the work. To review the project report, see the Final Notre Dame Report. Links to other reports and publications can be found on the Publications and Reports page of this website.